LIDKÖPING

LIDKÖPING SSB 62

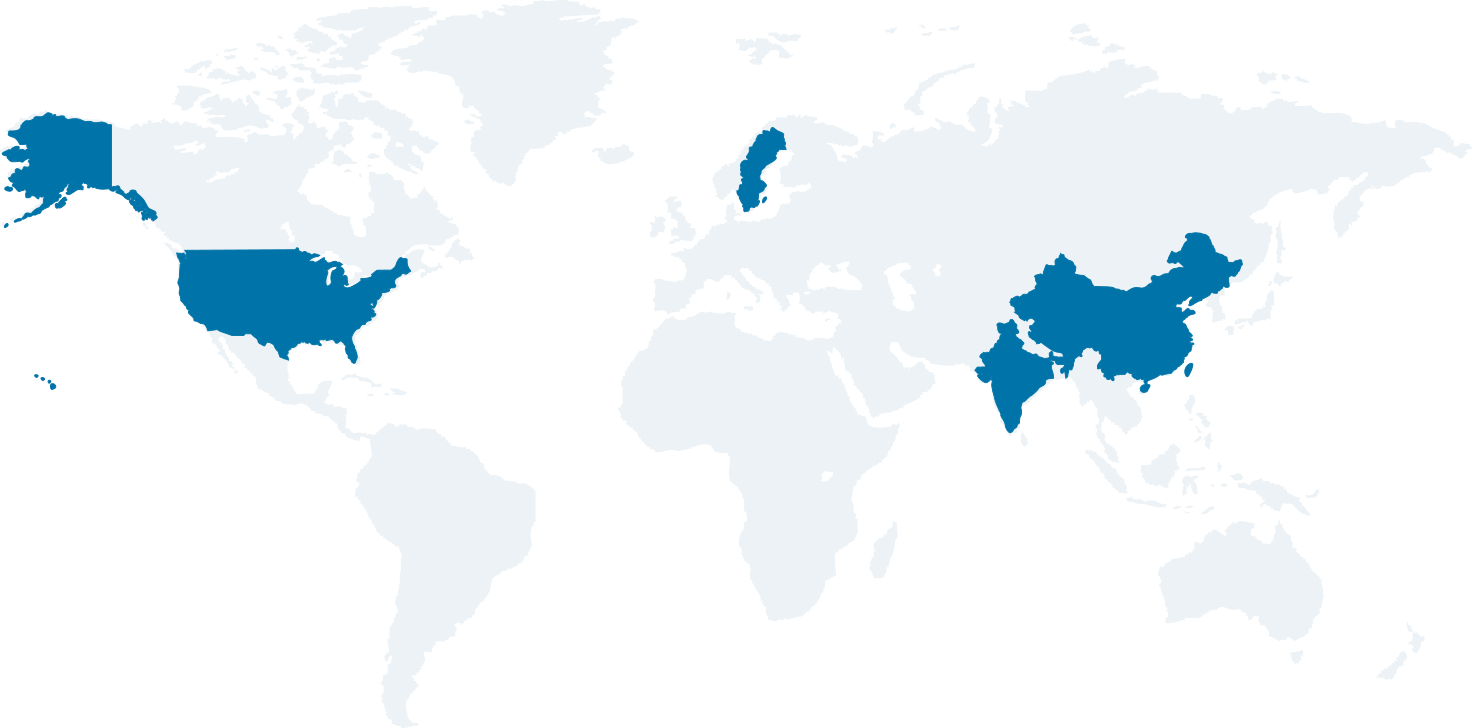

Worldwide leading global supplier of high precision grinding machines for 120 years, more than 10,000 machines installed around the world

UVA LIDKÖPING develops, markets, manufactures, and installs high-precision grinding machines with surrounding equipment within the area of high precision grinding. We market our products under the trademarks UVA LIDKÖPING, LIDKÖPING and UVA.

UVA customers are found among fuel injection technologies and other industries where the demands for productivity, precision and rational production methods are exceptional. UVA high precision grinding machines are suitable for grinding workpieces with dimensions between 0.5 mm - 160 mm.

LIDKÖPING customers are found in the bearing and automotive industry, where the highly automated manufacturing processes place great demands on productivity, precision and cost efficiency. LIDKÖPING wide range of high precision grinding machines is suitable for workpieces with dimensions between 5 mm - 820 mm combined with several grinding processes.

Service and trouble-free operation throughout the life-time of the machine

We can give you full support of spare parts, repairs of machines and components, machine refurbishing or upgrading.

GMT 12:00-22:00

Office: +1 508 634 4301

Cell: +1 513 375 8833

serviceboston@uvalidkoping.com

Speed, reliability and innovative solutions are critival for the machine tool maker who wants to serve the highly competetive automobile, bearing, hydraulic and other industries. That's why UVA LIDKÖPING is a preferred machine tool partner to the world's leading automobile, bearing and hydraulic producers.